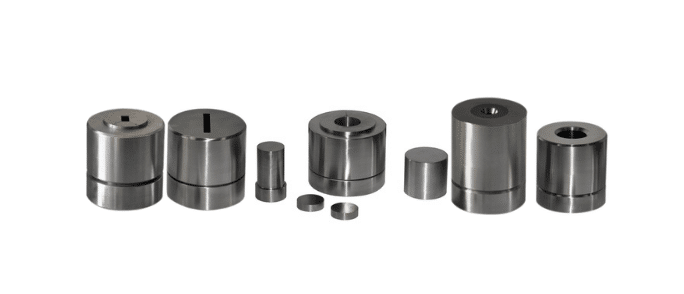

Exploring Circular, Square, Splitable, Hardened, and Heatable Variants

In the world of pellet production, the unsung heroes often go unnoticed—the pellet dies. These seemingly simple tools play a pivotal role in transforming raw materials into uniform, high-quality pellets, shaping industries ranging from agriculture to pharmaceuticals. Among the array of pellet dies available, each variant—Circular, Square, Splitable, Hardened, and Heatable—holds its unique capabilities, catering to diverse manufacturing needs.

Circular Dies: Precision in Motion

Circular pellet dies, characterized by their rounded shape, excel in providing consistent compression throughout the pelletizing process. Their design ensures an even distribution of pressure, resulting in uniformly shaped pellets. Industries reliant on consistent quality, such as animal feed and biomass, often rely on circular dies for their efficiency and reliability.

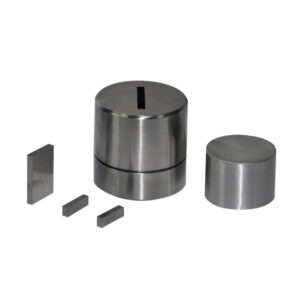

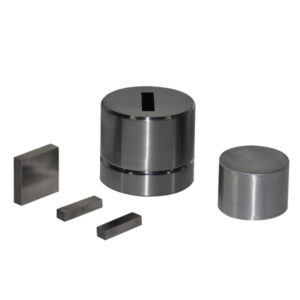

Square Dies: Defined Edge for Specialized Applications

In contrast, square pellet dies boast a more angular shape, lending themselves to specific applications that require defined edges in the resulting pellets. This variant finds favor in industries like pharmaceuticals or certain chemical manufacturing processes where precise shapes and edges are crucial.

Splitable Dies: Versatility and Adaptability

Innovations in pellet die technology have given rise to splitable dies, offering unparalleled versatility. These dies can be divided into segments, enabling easier replacement of worn-out parts without the need to replace the entire die. Such adaptability not only reduces downtime but also enhances cost-effectiveness in manufacturing processes.

Hardened Dies: Durability for Longevity

Hardened pellet dies are engineered with materials that undergo specialized treatments to enhance their durability. These dies withstand high pressures and abrasive materials, ensuring prolonged usage without compromising on the quality of the pellets. Industries dealing with abrasive materials, like wood pellets or certain minerals, benefit greatly from the longevity provided by hardened dies.

Heatable Dies: Precision Temperature Control

Temperature control is crucial in certain pelletizing processes. Heatable dies come into play by allowing precise regulation of temperatures during compression, ensuring optimal pellet formation. Industries dealing with materials sensitive to temperature fluctuations, such as certain plastics or pharmaceuticals, find these dies indispensable.

Conclusion

The world of pellet dies is diverse and multifaceted, catering to a spectrum of manufacturing requirements across industries. From the precision of circular dies to the adaptability of splitable variants, and from the durability of hardened dies to the temperature control of heatable ones, each type offers a unique set of advantages.

Understanding the nuances and capabilities of these pellet dies is paramount for industries seeking efficiency, quality, and cost-effectiveness in their pellet production processes. As technology advances, these dies continue to evolve, promising even greater precision, durability, and adaptability, further revolutionizing the landscape of pellet manufacturing.

In essence, behind every high-quality pellet lies the craftsmanship and precision of the often-overlooked pellet die—a testament to the intricate engineering that shapes the building blocks of numerous industries.